Drill

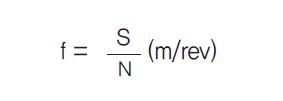

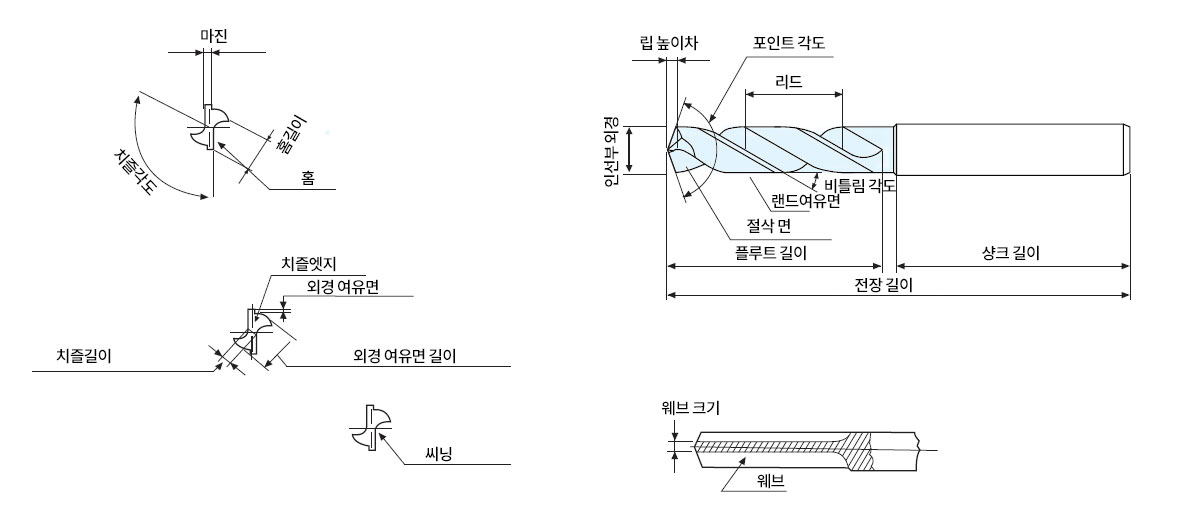

Nomenclature of Drill

Nomenclature of Drill

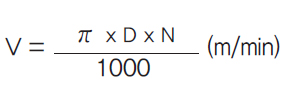

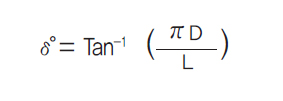

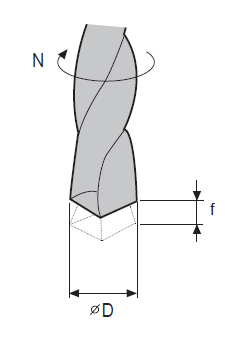

Machining formula

Working of Main Angle

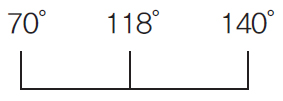

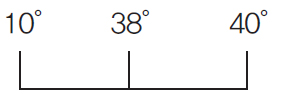

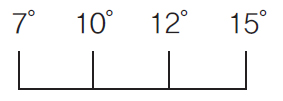

| Point Angle | Torsional Angle | Lip Relief Angle | |

|---|---|---|---|

Small → Thrust → Large |

Good → Chip emission → Bad Large → Tool toughness → Small |

Small → Vibration → Large |

|

| Point Angle | Torsional Angle | Lip Relief Angle | |

• D : Diameter of drill • N : Revolution • π : (3.14) (m/min) (mm) (rpm) |

• S : Depth of cut per min • N : Revolution (mm/rev) (mm/min) (rpm) |

• D : Diameter of drill • L : lead • π : (3.14) (mm) (mm) |

Drill Trouble Shooting

Drill Trouble Shooting

| Trouble issue | Cause | Solution |

|---|---|---|

| Drill does not enter the workpiece |

|

|

| Margine chipping |

|

|

| Blance of cutting edge |

|

|

| Chipping of cutting edge |

|

|

| Broken of tang |

|

|

| Broken for brass work |

|

|

| Crack of Drill core |

|

|

| Over hole size |

|

|

| Broken for Flute edge |

|

|

| Irregular chip size |

|

|

| Rough hole |

|

|